CATALOG

Our equipment has been standardized so that each product has its own identification code by which you can easily determine its parameters. Our engineering team will be happy to help you choose the most suitable equipment for your needs.

Order code: VIBE . AA . BB . CC . WW . XX

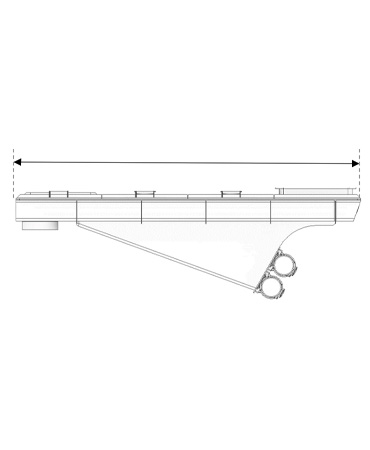

AA - FEEDER LENGHT

10 – 1000 mm

12 – 1250 mm

15 – 1500 mm

17 – 1750 mm

20 – 2000 mm

22 – 2250 mm

25 – 2500 mm

27 – 2750 mm

30 – 3000 mm

32 – 3250 mm

35 – 3500 mm

37 – 3750 mm

40 – 4000 mm

42 – 4250 mm

45 – 4500 mm

47 – 4750 mm

50 – 5000 mm

52 – 5250 mm

55 – 5500 mm

57 – 5750 mm

60 – 6000 mm

SP – Special order

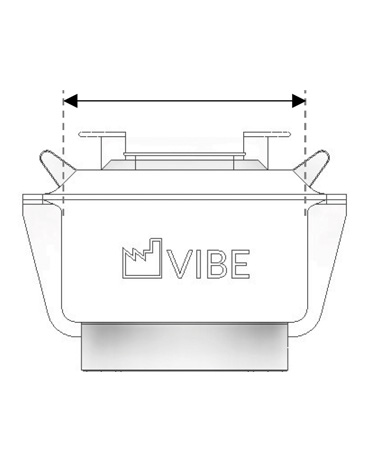

BB - FEEDER WIDTH

40 – 400 mm

45 – 450 mm

50 – 500 mm

55 – 550 mm

55 – 550 mm

60 – 600 mm

65 – 650 mm

70 – 700 mm

75 – 750 mm

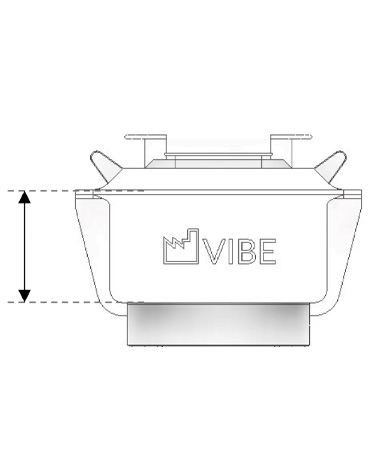

CC - FEEDER HEIGHT

10 – 100 mm

15 – 150 mm

20 – 200 mm

25 – 250 mm

30 – 300 mm

35 – 350 mm

40 – 400 mm

45 – 450 mm

WW - FEEDER CAPACITY

20 – 20 t/h

25 – 25 t/h

30 – 30 t/h

35 – 35 t/h

40 – 40 t/h

45 – 35 t/h

50 – 50 t/h

55 – 55 t/h

60 – 60 t/h

65 – 65 t/h

70 – 70 t/h

75 – 75 t/h

80 – 80 t/h

85 – 85 t/h

90 – 90 t/h

95 – 95 t/h

XX - WEAR LINING

Hardfacing steel:

V1 – Vautid 5+3

V2 – Vautid 6+4

V3 – Vautid 10+10

Wear-resistant steel:

H1 – Hardox x4

H2 – Hardox x6

H3 – Hardox x8

H4 – Hardox x10

RX – Raex 500

Plastics:

PE – PE-1000

TV – Tivor 1000

Stainless steel:

SN – Stainless steel

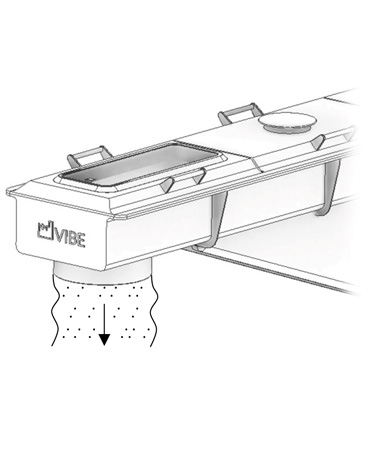

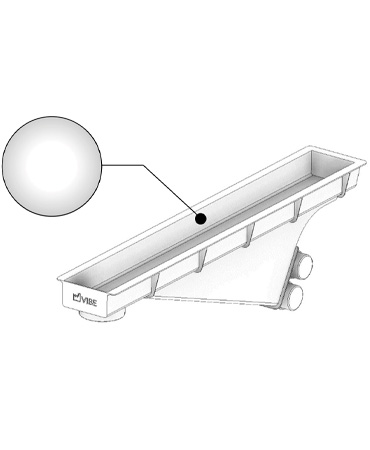

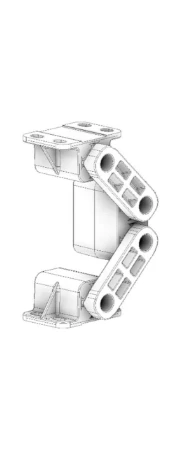

VIBRATION INSULATION

We use a dedicated suspension solution for conveying equipment using vibration. The size of the suspension and their arrangement is adjusted individually for the selected device.

DEDICATED CONTROL SYSTEM

A special system that allows us to achieve a dosing precision of up to 0.05% while maintaining the highest listed efficiencies. Intuitive control panel allows to view and control working parameters in full range.